Gasification burner and quench

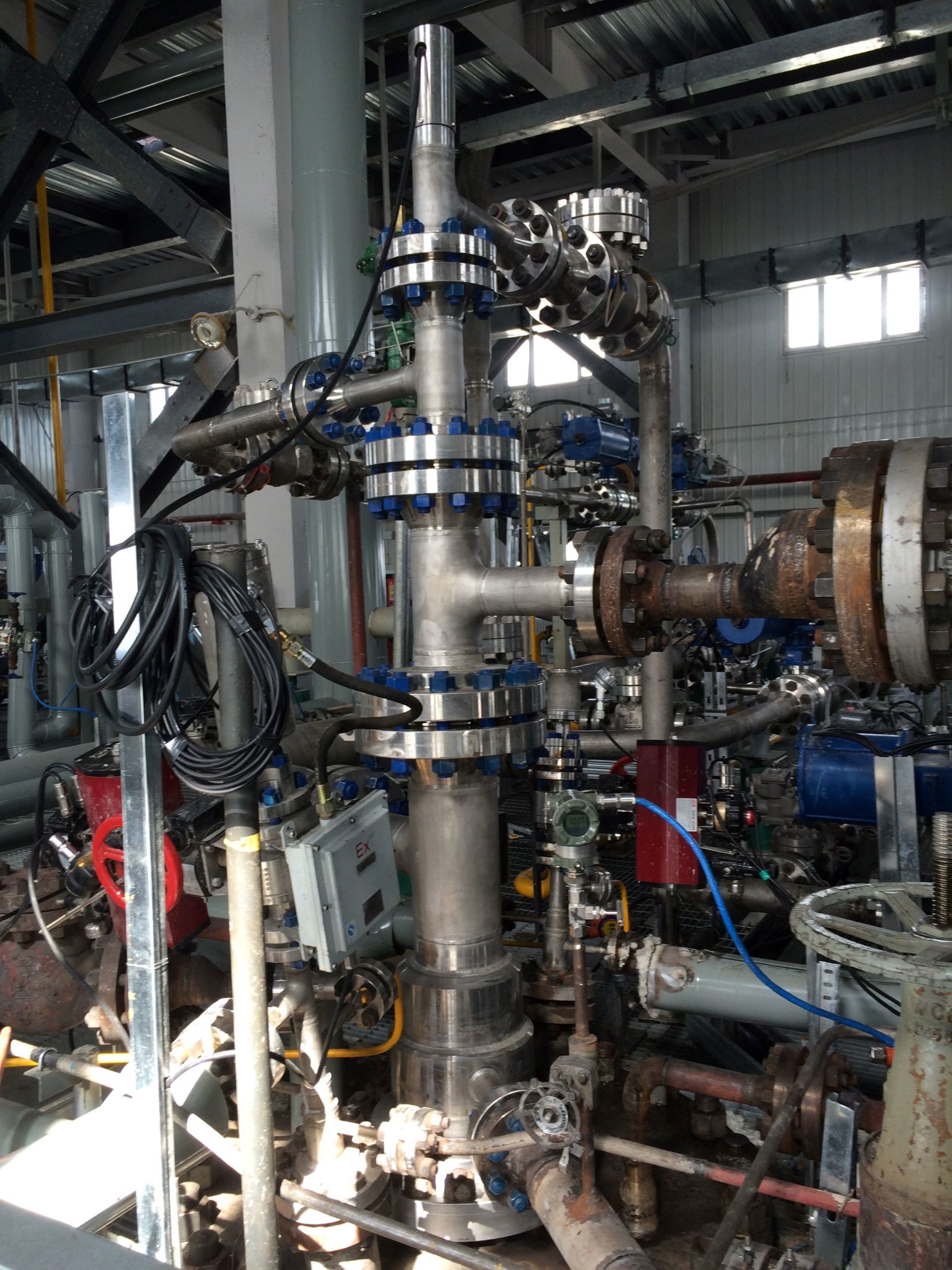

BAEEC is engaged in the design, manufacture and maintenance of various gasification process burners and quench equipment. Related technology and equipment are widely used in nearly 100 enterprises, which business scope covers coal chemical industry, petroleum and petrochemical industry. The products include preheating burner of gasification device, coal water slurry burner, residual oil burner, pulverized coal burner, quench equipment, etc. The market share of coal water slurry burner is more than 80%, which is widely recognized by customers at domestic and abroad.

Technical capacities:

Supporting mainstream coal gasification processes such as AP, Huali multi-nozzles, Jinhua furnace, Xibei Institute, Jinju furnace, Aerospace furnace, Shell, and E-Gas.

It is suitable for gasification pressure classes of 2.0Mpa, 4.5Mpa, 6.5Mpa, 8.7Mpa, etc.

It is suitable for 2.8m, 3.2m, 3.6m, 3.88m, 4.2m and other specifications of gasifiers.

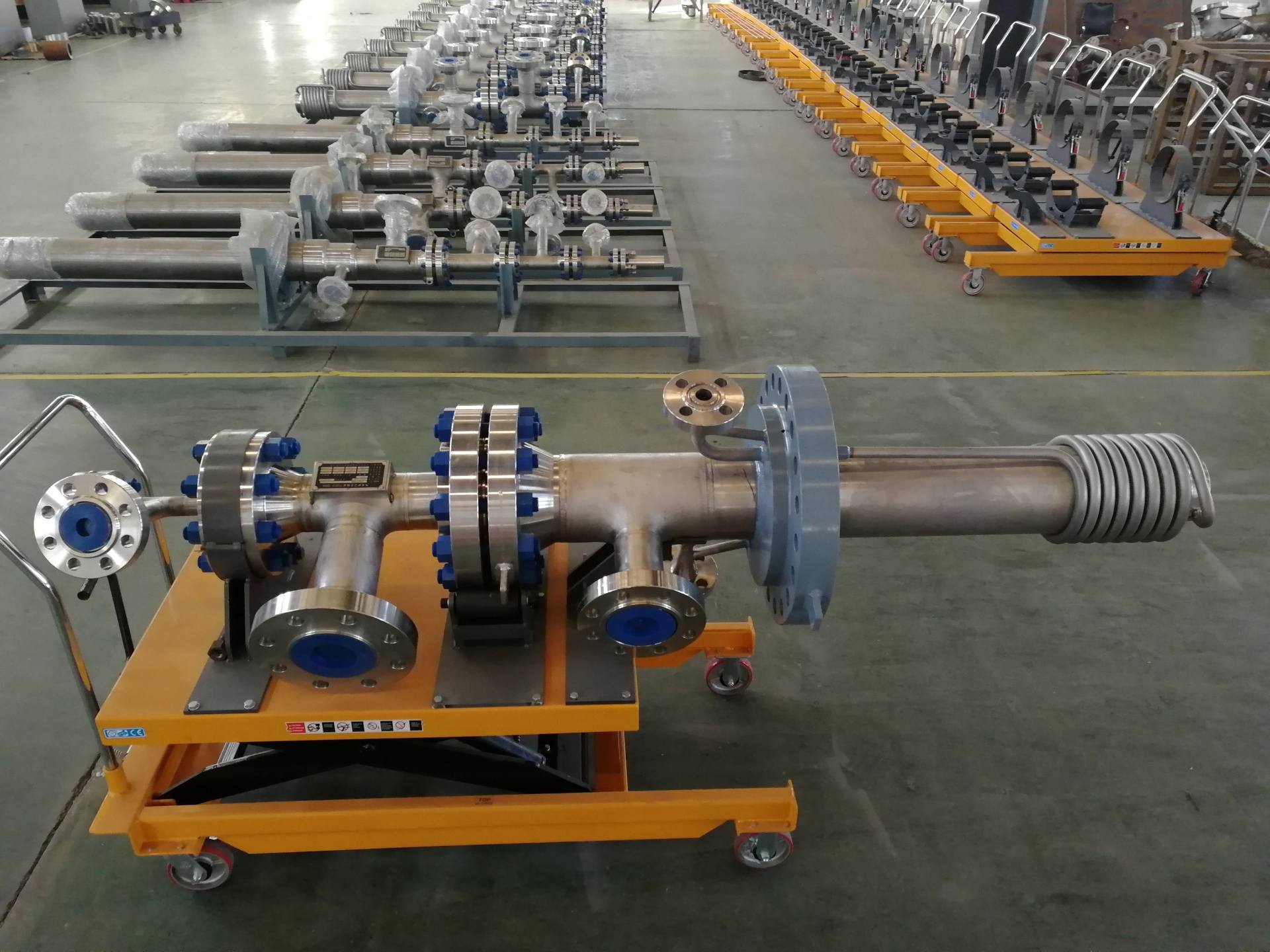

The main specifications of the burner include 5'', 6'', 8'', 10'', 12'', 14'', 16'', 18'', 20'' and so on.

The effective gas ratio exceeds 80%, and the carbon conversion rate can reach 99%.

The burner is made of imported nickel-based pipe, and the nozzle is made of aerospace wear resistant and thermal barrier material and technology, which greatly improves the high temperature resistance and erosion resistance of the equipment.

The long operation period burner has been running continuously for more than 200 days, which is the world’s leading level and has obtained a number of technical patents.

In the field of coal water slurry gasification performance covering all gasification process suppliers and service providers.

|

|

| Rocket system | Gasification system |

|

| Gasifier |

|

|

| Process burner | Fuel gas burner |

|

|

| Quench ring | Downward tube |

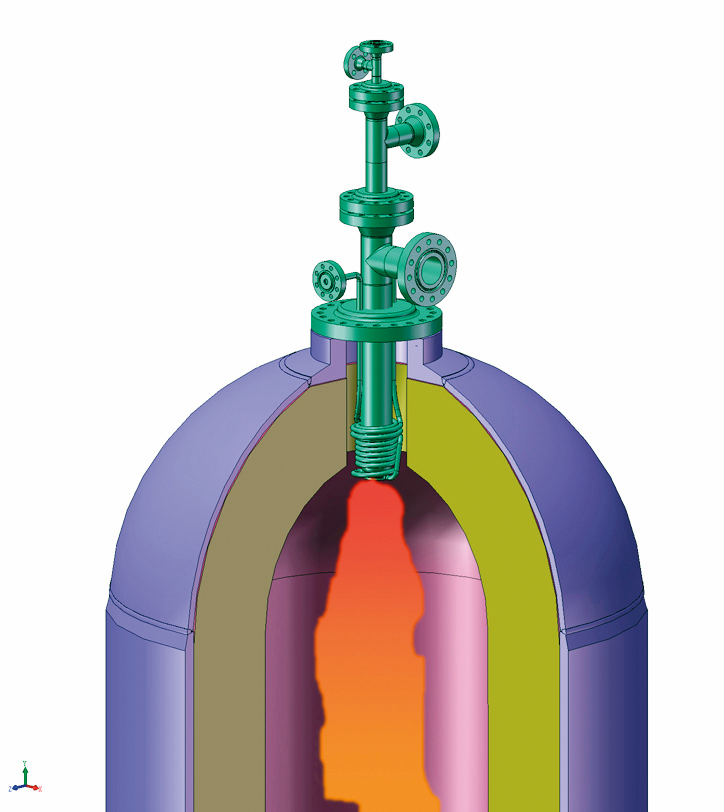

Gasification burner

Gasification burner is the heart of coal water slurry pressurized gasification process, which service life and performance seriously affects the gasification operation cycle and the economic benefit of the whole plant.

Coal water slurry burner is the worst working condition and the most difficult special non-standard burner in high temperature, high pressure and pure oxygen conditions.

Combination burner for domestic coal-water slurry water-wall gasifier is independent research and development by BAEEC, which setting intelligent ignition, oven, feeding and remote automation in one.

|

|

| Residual oil burners | Pulverized coal burner |

|

|

| Combined burner | Coal water slurryburner |

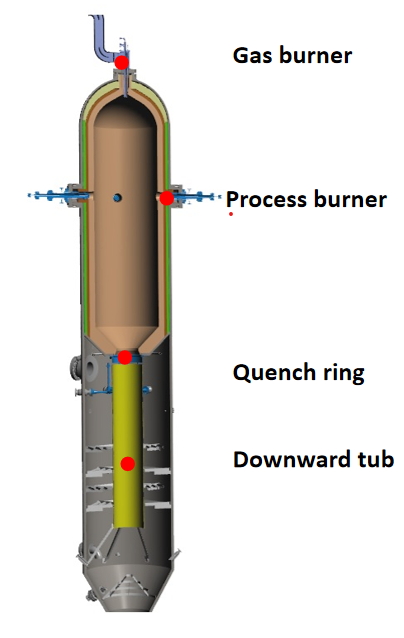

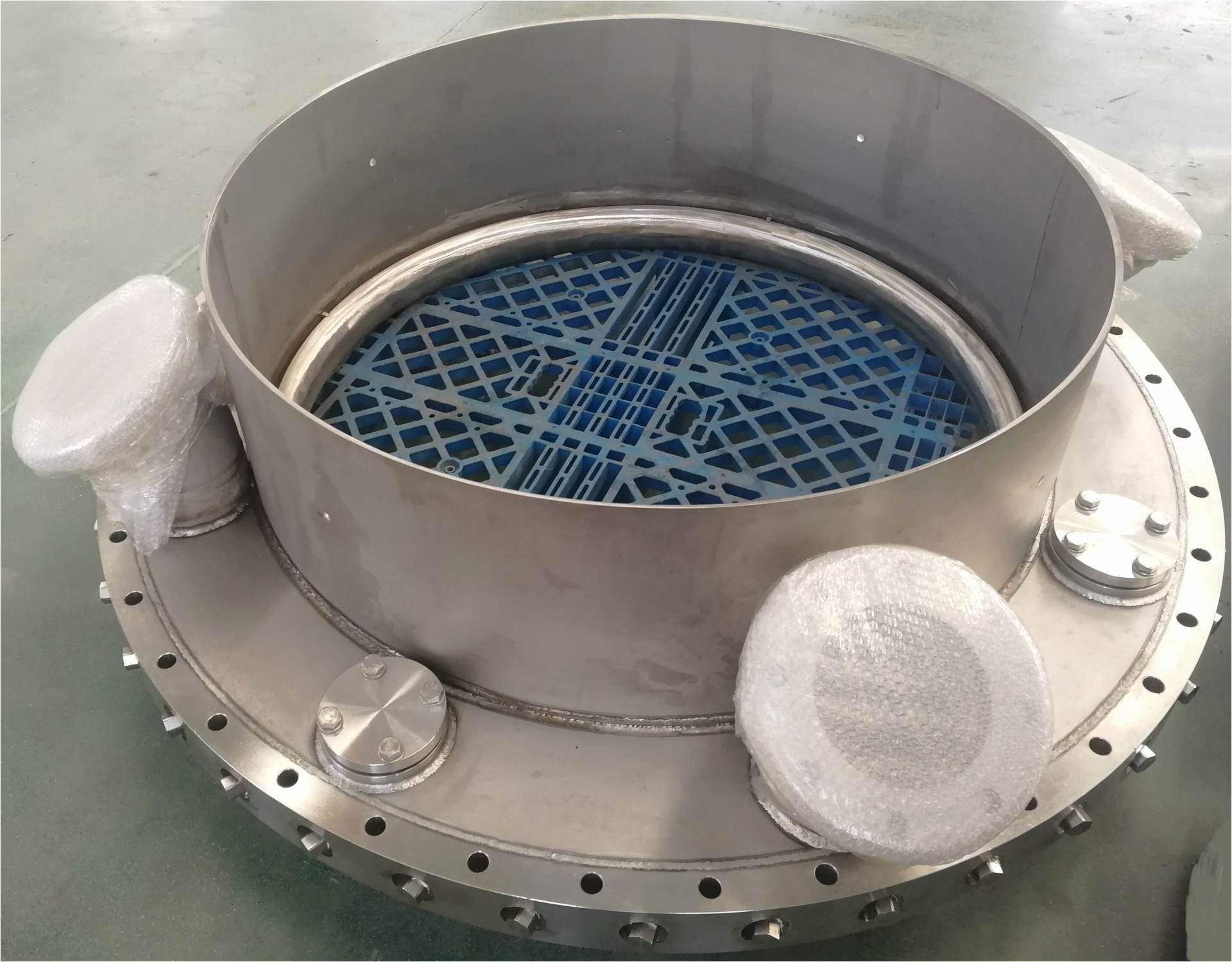

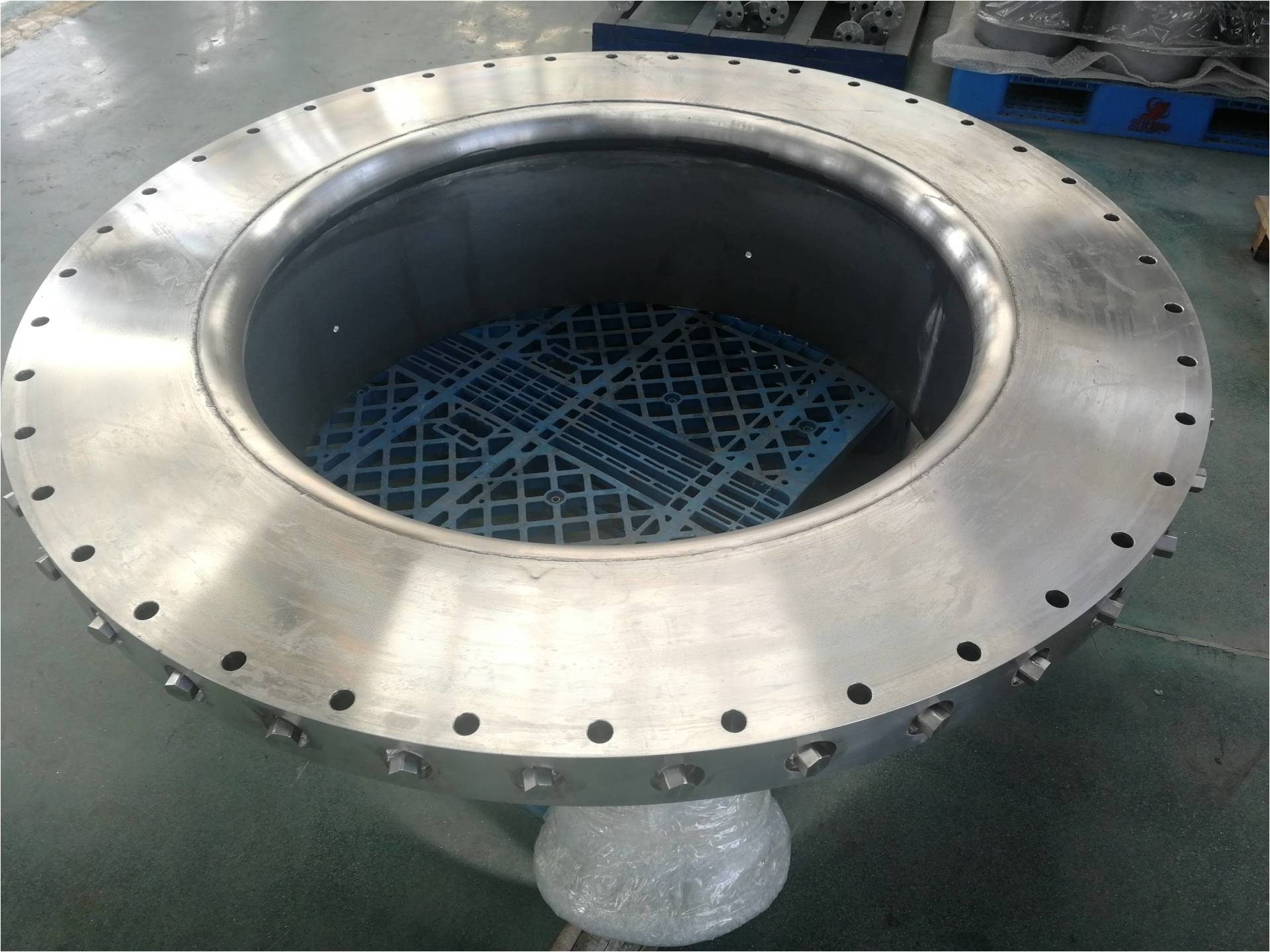

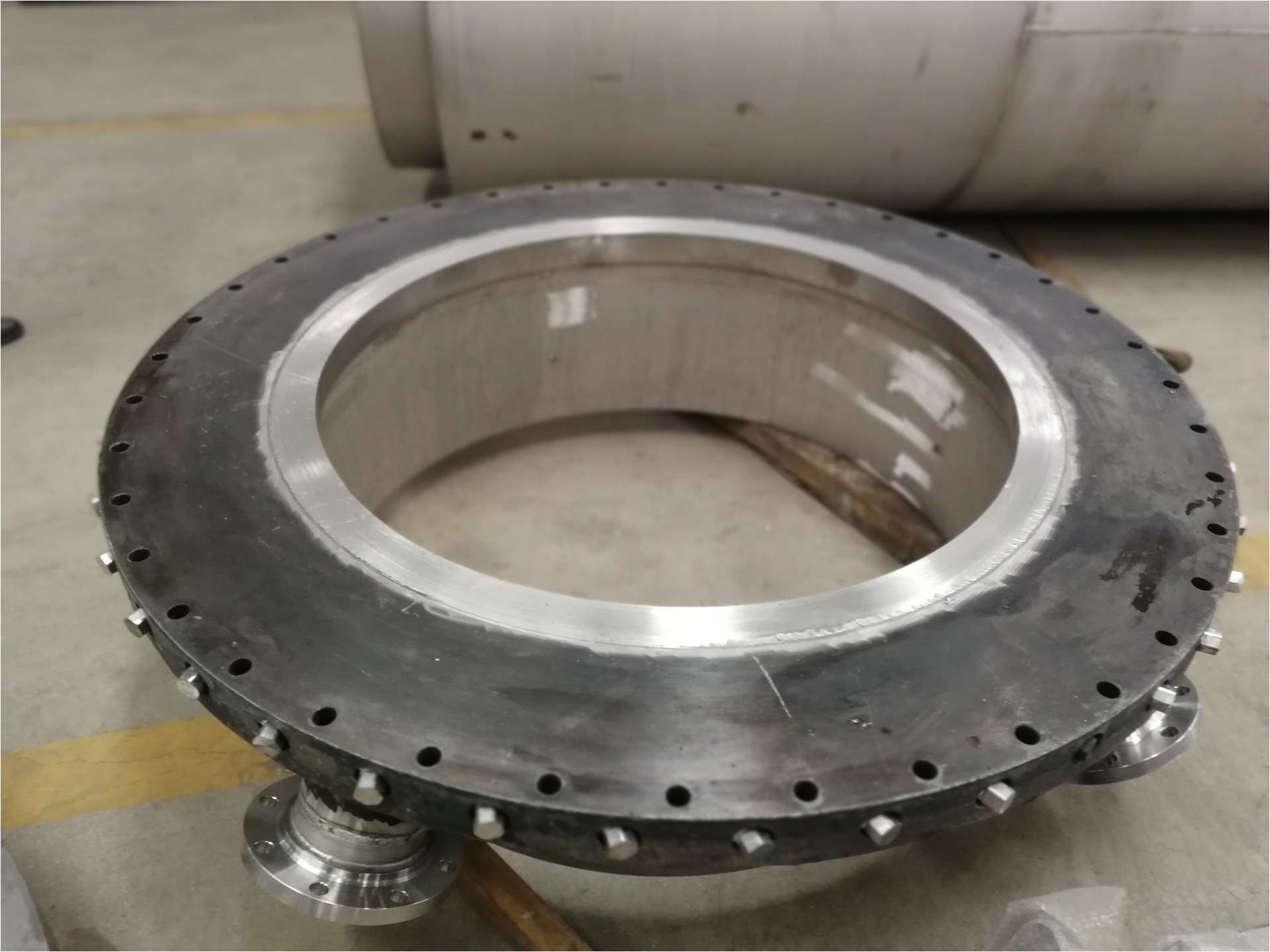

Quench equipments

Supporting process contractor research and development of a furnace cooling equipment, provide feasibility optimization design scheme.

|

|

| Quench ring | |

|

|

| Downward tub | |

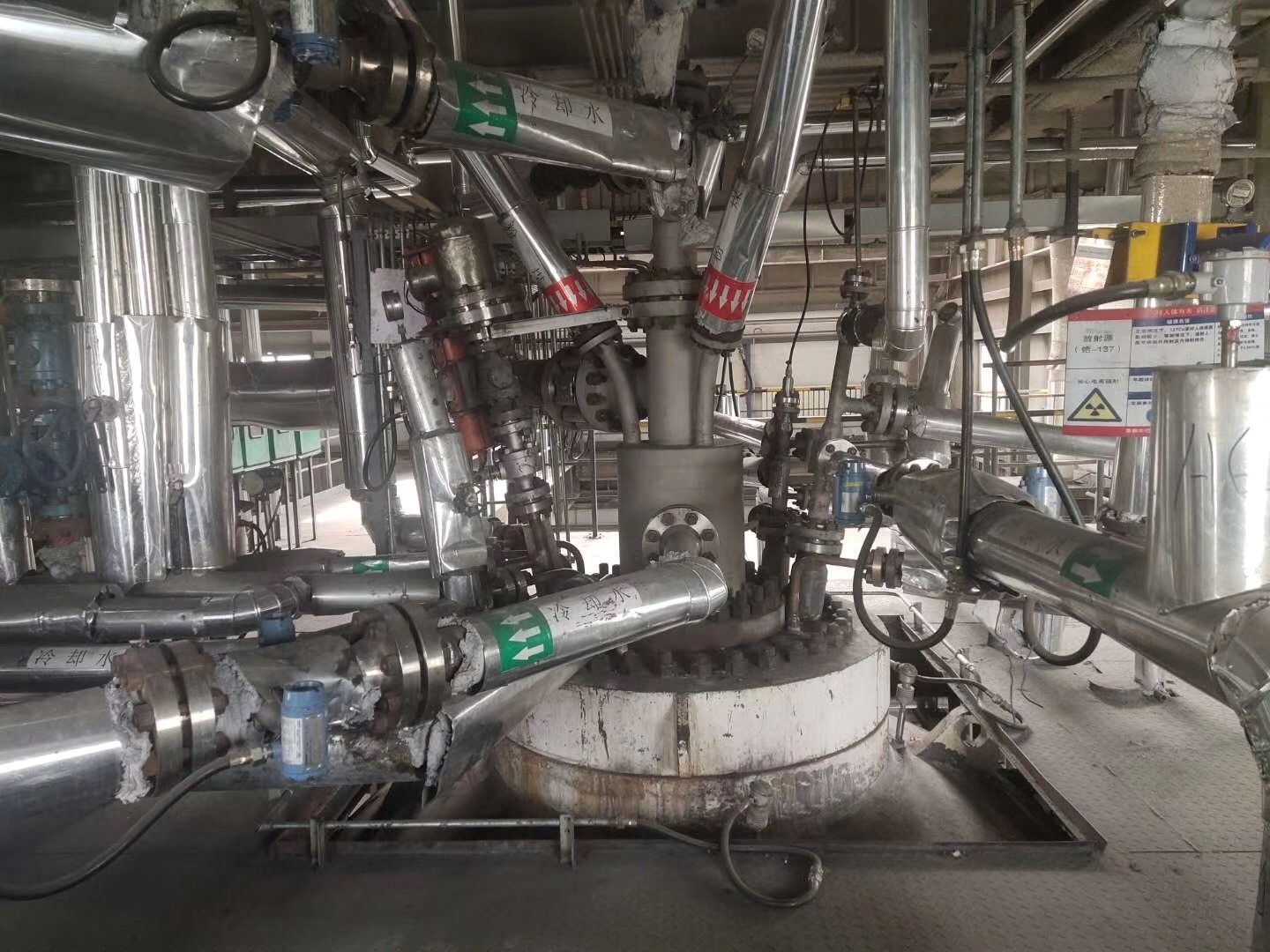

After sales service

Optimization design: Design, repair and transform burner for coal type change and load adjustment

Quick response: special transport person is responsible for the maintenance within a week

Annual capacity: more than 1000 maintenance orders per year, long-term after-sales service framework.

Innovative maintenance: Application of aerospace technology to optimize the design, break the life bottleneck. Expand the life extension technology.

|

Conventional burners maintenance before and after |

Combined burner maintenance before and after |

|

|

| Quench ring before and after maintenance | |

|

|

| Burner defore and after life extension modification | |