Engineering

Waste Gas and Liquid Incineration System

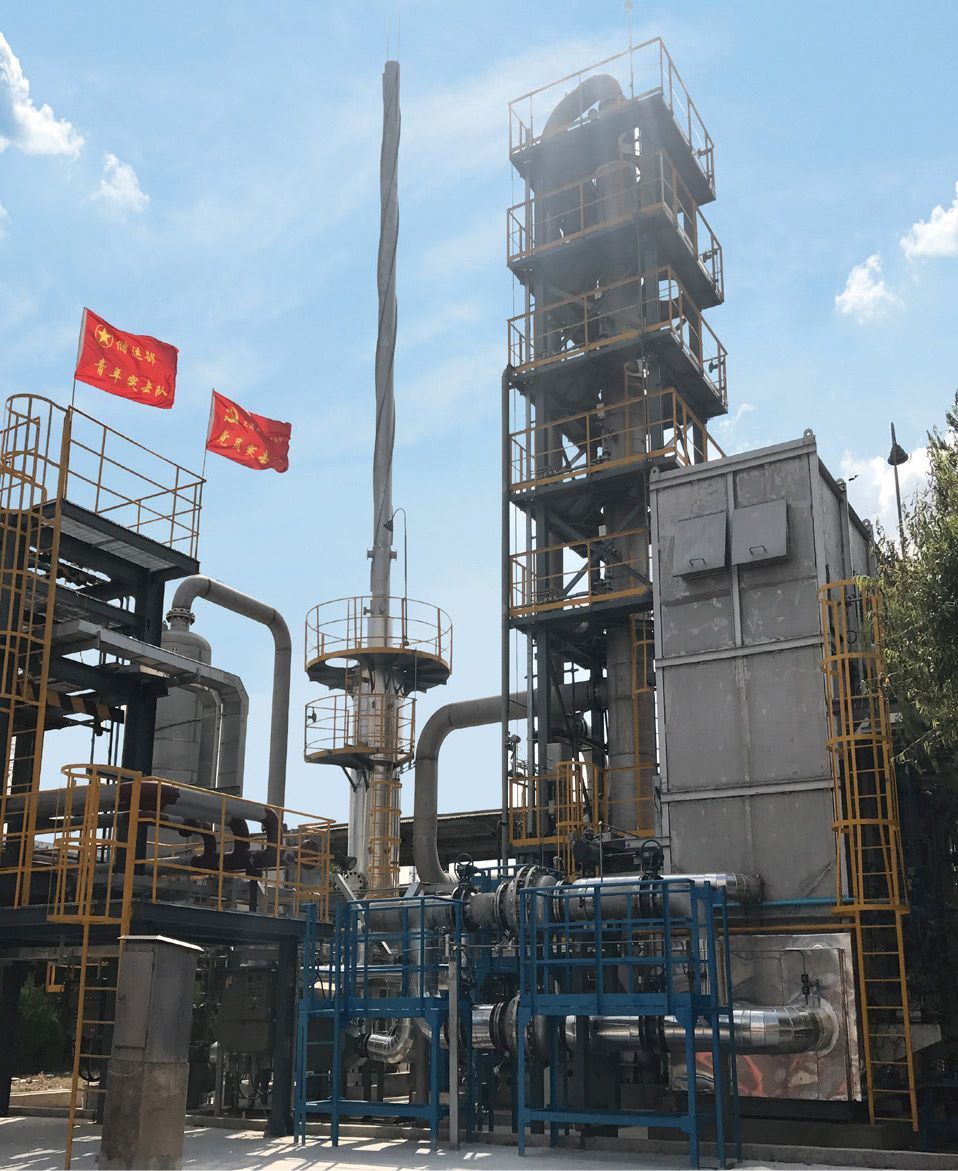

Safe and reliable incineration environmental protection solutions can be customized by BAEEC in many industries, such as the chlor-alkali industry, fluorochemical industry, coal chemical industry, oil refining, pesticide, medicine, polyester, chemical fiber, silicone, polysilicon, hexanedioic acid, acrylic acid, acrylonitrile, caprolactam, BDO (1, 4-butanediol), MTO (methanol to olefin), and so on. The incineration system can environmentally treat the waste gas and liquid containing fluorine, chlorine, silicon, nitrogen, sulfur, phosphor, and salt.

Technical Capacities:

- BAEEC adopt low Nox combustion technology and select the optimal airflow distribution mode to deliver great combustion performance;

- The waste heat boiler adopts unique thermal protection structure and modular, hydrothermal media technology;

- Complete BMS combustion control system, PLC/DCS control system and SIS safety system;

- It is recognized as "chemical waste incineration engineering center" by China petroleum and chemical industry federation and China environmental protection association of chemical industry.

- The waste liquid and gas incineration environmental protection technology becomes one of the first system in The Catalogue of Key Technologies for Environmental Protection in Petroleumand Chemical Industry;

- BAEEC have more than 40 patented incineration technologies;

- More than 200 incineration systems are in stable operation in many key projects;

|

|

| Incineration unit of waste gas and liquid containing fluorine (SINOCHEM Taicang) | |

|

|

| Incineration unit of crylic acid waste gas and liquid (Pinghu Petrochemical) | VOC RTO System (Sinopec Shanghai Petrochemical) |

Fluorine and Chlorine Containing Waste Gas and Liquid Incineration System

- In 1995, successfully developed waste gas and liquid waste incineration units for the 80,000-ton/ year VCM project of Tianjin Dagu Chemical Plant, which filled the gap in the localization of environmental incineration devices in the chlor-alkali industry.

- The ‘Pollution-free incineration technology of chemical chlorine waste liquid waste gas’ developed for Qilu Petrochemical Chlorine-alkali Plant passed the identification of scientific and technological achievements of Sinopec’s major domestic equipment.

- Use negative pressure quench process to completely solve the problem of dioxin regeneration.

- Main users include Qilu Petrochemical, Shanghai Chlor-alkali, Jiangxi Xinghuo, Shandong Dongyeu, Hebei Xingfa, Qinghai Salt Lake, Changshu 3F, ARKEMA (France), Jiangsu Xinpu (Singapore), Sinochem Taicang and other enterprises.

|

|

| Iincineration unit of waste gas and liquid containing fluorine (ARKEMA) | Inxineration unit of waste gas and liquid containing fluorine (Changshu 3F) |

|

|

| Incineration unit of waste gas and liquid containing chlorosilane (Phase II of Shandong Dongyue) | |

|

|

| Incineration unit of waste gas and liquid containing chlorofluorocarbon (Phase II of Qilu petrochemical chlorine-alkali plant) | Incineration unit of waste gas and liquid containing chlorofluocarbon(Phase III of Shanghai Chloro-alkli plant) |

Salt-containing organic waste liquid incineration system

- According to the different types and concentrations of salt in organic waste liquid, integrated incineration boiler process and negative pressure quench process have been developed, which effectively salve the problems of melting salt corrosion and ash blockage;

- Integrated incineration boiler process combines high temperature incineration, waste heat utilization and inorganic salt recovery;

- Negative pressure quench process to completely solve the problem of dioxin regeneration;

- The first domestic set of waste lye incineration unit for the MTO plant was developed in Shenhua Baotou;

- ‘HT pesticide waste residue wastewater incineration treatment complete set technology and equipment’ has passed CPCIF’s scientific and technological achievement appraisal, and has been strongly recommended by CCPIA in pesticide industry;

- It can be widely used in medicine, pesticide, BOD, MTO, caprolactam, acrylic acid, acrylonitrile etc. The main customers include Shenhua Coal-to-oil, China Chengda, Shanghai Huayi, Shijiazhuang Refining, Lianhua Technology, Yaben Chemical, Cangzhou Xuyang, Weifang Xinlu, Zhongtian Hechuang, Wanzhou Petrochemical (Taiwan), Taiwan Changlian and other enterprises.

|

|

| Incineration unit of waste gas and liquid in pesticide industry (Nantong Yaben) | Incineration unit of potassium amino acid salt waste liquid (Shandong Xinhecheng) |

|

|

| Incineration unit of waste liquid containing sodium salt(2 sets in Xinjiang Lanshan Tunhe) | |

|

|

| Quench incineration unit of MTO waste alkli liquor (Shenhau Yulin) | Incineration unit of waste gas and liquid in pharmaceuticals industry (Taizhou Lianhua Technology) |

|

|

| Incineration unit of acrylonitrile waste gas and liquid (Shandong Bohui) | |

S and N containing organic waste liquid incineration system

- Developed the domestic first set of methionine waste liquid and waste gas incineration system for Chongqing Ziguang Tianhua Methionine Co., LTD.

- Developed the domestic first set of waste liquid and waste gas incineration system with laughing gas for Xinjiang Tianli High-tech Co., LTD.

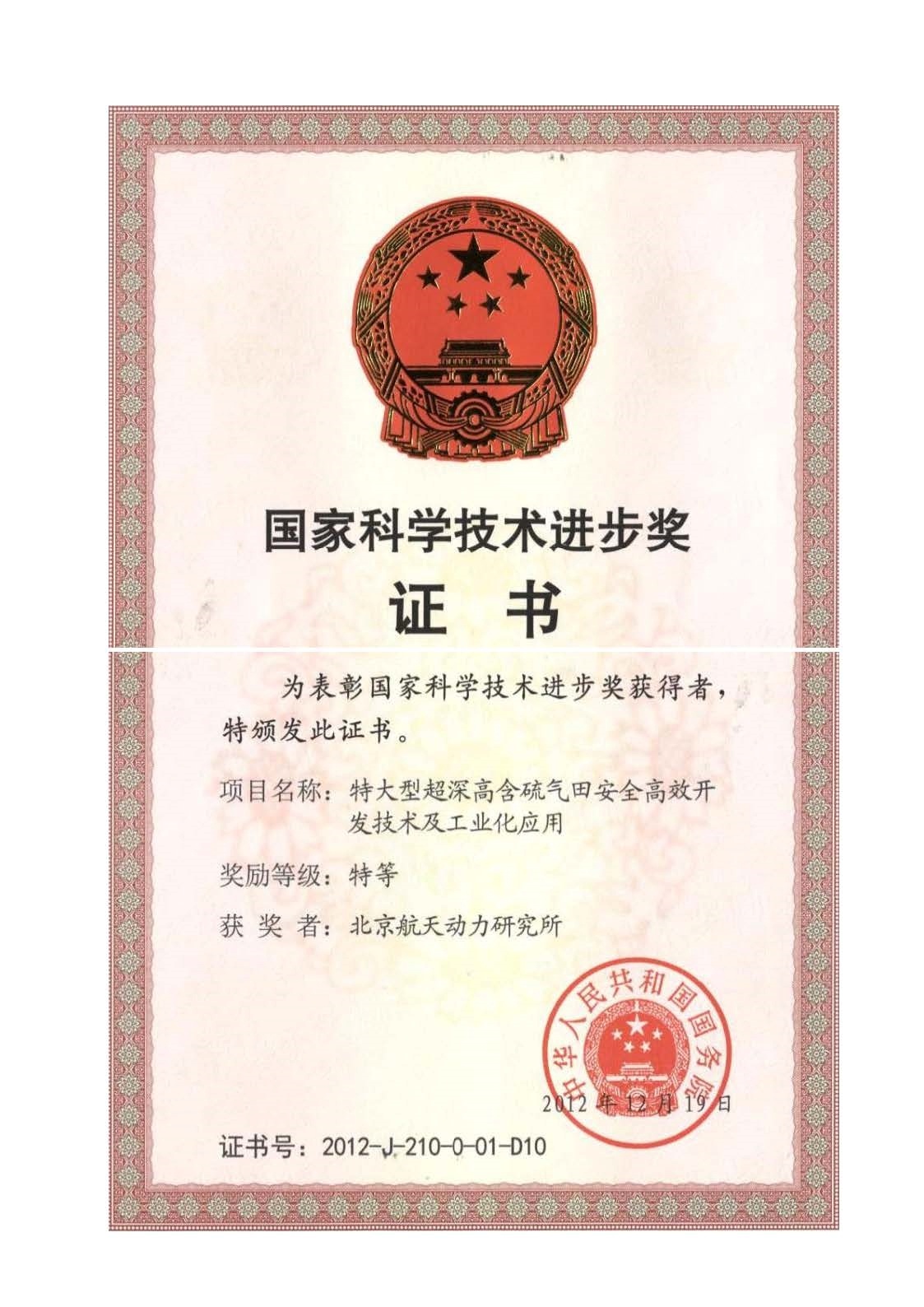

- High H2S natural gas incineration won the National Science and Technology Progress Award.

- Main customers include Yanshan Petrochemical, Shanghai Petrochemical, Ningbo Wanhua, Tangshan Xuyang, Shenhua Zuneng, Zhongyuan Oilfield, Jiangsuer Bang, DSM Oriental (Netherlands) etc.

|

|

| WSA unit of H2S gas (Bao steel) | Incineration unit of adipic acid waste gas (Xinjiang Tianli) |

|

|

| Mobile exploration well incinerator (Zhongyuan Oilfield), which won the National Science and Technology Process Award | |

|

|

| Incineration unit of methionine waste liquid and waste gas (Chongqing Ziguang) | Incineration unit of PC waste gas (Shandong Lihuayi) |