Engineering

Waste Heat recovery Boilers and Industrial Furnaces

Waste Heat Boilers

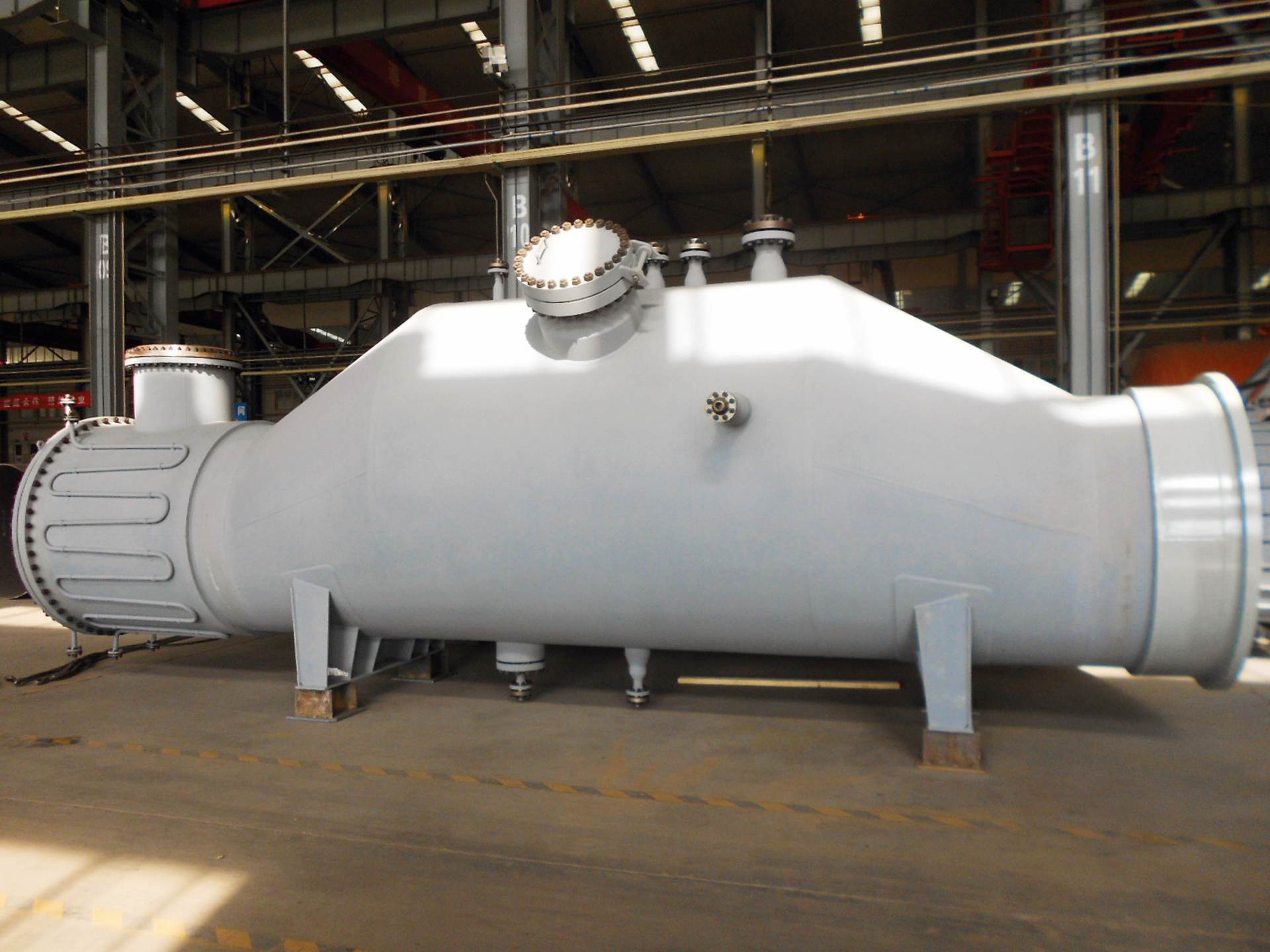

The heat transfer equipment which uses hot stream from the chemical production process as the heat source for generating steam includes shell and tube waste heat recovery boilers and watertube waste heat recovery boilers.

- Shell and tube waste heat recovery boilers

Relying on the independently developed thermal calculation software and rich operating experience, we have modified the calculation results, aiming to guarantee excellent performance and cost-effectiveness of the boilers. A built-in regulating mechanism may be designed according to the process needs, to maintain required process gas outlet temperature. Through the analog simulation of temperature field of the flexible thin-walled tube plate structure and according to the structure coupling stress nephogram, the fragile parts have been optimized to extend the equipment life time and improve the reliability.

- Watertube waste heat recovery boilers

Watertube waste heat recovery boilers are of modular structure, use water as the heat transfer medium, and extract heat from hot flue gas to prevent low temperature corrosion, achieve high-quality manufacture and installation, and shorten the installation period. On account of the fact that the flue gas contains dust, salt, and corrosive substance, a mature structural design is adopted to ensure long-term continuous operation of the equipment.

|

|

| Shell and tube waste heat boiler | Water tube waste heat boiler |

Hot-blast heater

The high-temperature gas generated from combustion is used to heat the air by means of heat transfer enhancement, so as to provide hot air at required temperature and flow rate for drying, and also to provide hot air source to compound fertilizer industry, coal chemical industry, and other industries containing the drying process.

Technical capacities:

-

High fuel flexibility, it can use diesel, natural gas, synthetic gas and low calorific value gas as fuel;

-

1:20 maximum load regulating ratio;

-

Multilayer thermal insulation structure issued, with the thermal efficiency over 97%;

-

Automatic ignition and start/stop functions are available, and the thermal load can bead adjusted automatically according to the hot air outlet temperature;

-

The air-fuel ratio can be adjusted automatically, while maintaining the flue gas oxygen level≤5%;

-

Perfect security interlocking and alarm functions are provided.

|

|

|

| Hot blast heater | |

CS2 Reaction furnace

Reaction furnace is the key equipment of decomposition and reforming reaction, strict temperature field distribution and accurate system control. We have a series CS2 reaction furnaces and design capacity of complete set of tubular reactor .

Technical capacities:

● Low NOx burners are used to effectively reduce the volume of Nitrogen oxides;

● Material conversion ratio reaches 96%;

● Fuel burning ratio reaches 99%;

● The whole thermal effectiveness of the furnace is above 90%.

|

|

| CS2reaction furnace | |

Technical Modification of Industrial Boilers

BAEEC can undertake the energy saving and environmental protection, changes in fuel structure, improve the level of automation, and increase the thermal efficiency etc. technical modification of boilers in power plants, steam boilers, various waste gas and waste liquid incinerators, etc. We have provided many large-sized state-owned enterprises such as Sinopec Shanghai Petrochemical Company Limited, Sinopec Yangzi Petrochemical Company Ltd., Sinopec Beijing Yanshan Company, Sinopec Jilin Petrochemical Company, Sinopec Maoming Company, and Sinopec Lanzhou Petrochemical Company with a complete set of engineering services from technical scheme demonstration to engineering & design, supply of equipment and instruments, and onsite commissioning.

Technical capacities:

● Liquefied gas, natural gas, petroleum refinery gas, blast furnace gas, converter gas, coke-oven gas, generator gas and city gas can be used as fuel gas;

● Light oil, heavy diesel oil, heavy oil, tar, residual oil and asphaltic oil can be used as fuel oil, and cold-state electronic auto-ignition is feasible;

● The oxygen content adjustment and selective ratio control can be obtained;

● The fuel oil atomization is satisfactory with small and evenly-distributed particle size;

● The combustion efficiency is over 99.9%;

● The length, cone angle and shape of flame can be customized;

● The flow rate can be controlled across a very wide range and the regulating ratio can reach 1:5;

● Automatic control and real-time monitoring can be achieved.

|

|

| Technical modification of combustion system | |